The “Wake Up Call” for Upgrading

The manufacturer has been approached by sales teams from consulting companies who tried to sell the proposal to upgrade their Navision 4.0 SP2 application to NAV 2009 SP1.

The sales teams made “Wake Up Call” that support period for the manufacturer’s versions would end soon or had ended already. The application provider was advertising the benefits to upgrade on their web site. Some consulting firms were saying the manufacturer might have a cracked system as there were some issues they did not know the root causes.

Some people were saying that tech industry has mastered the art of “Up selling”. Some worried that software makers and the channel distributors combined to convince people to buy new software that they definitely don’t need.

Some other people were worried that it might hurt as the manufacturer’s version was falling behind by a gap of two versions.

Upgrading to NAV 2009 for the “Good Reasons”

EBITA Systems was retained to perform an analysis to see if the manufacturer needs to upgrade to the new version. EBITA Systems performed a thorough evaluation so the manufacturer could make informed decisions.

Why vendors release upgrades?

EBITA Systems explained that vendors need to ensure their products are competitive in term of features and performance. Also, vendors need to create demand.

What are in the upgrades? EBITA Systems explained that vendors often offer or try to offer extra incentive to upgrade, like a significant interesting new feature.

Why are you upgrading?

EBITA Systems explained that it is normally not for fashion and status symbols. It could be a matter of want than need. It could be being pushed by vendors and channel distributors. There could be real compelling reasons to upgrade.

What do people actually use the system for?

Despite the long list of great features for the system, many people only use their systems for a limited set of things. It is very likely that a lot of people are paying a premium to own a fancy ERP system that merely does bookkeeping. EBITA Systems further asked what challenges people encountered that the current system might or might not be able to help.

Identifying The “Compelling Reasons” For Upgrade

EBITA Systems presented some “compelling reasons” that would make sense for the manufacturer to go for upgrade.

New features

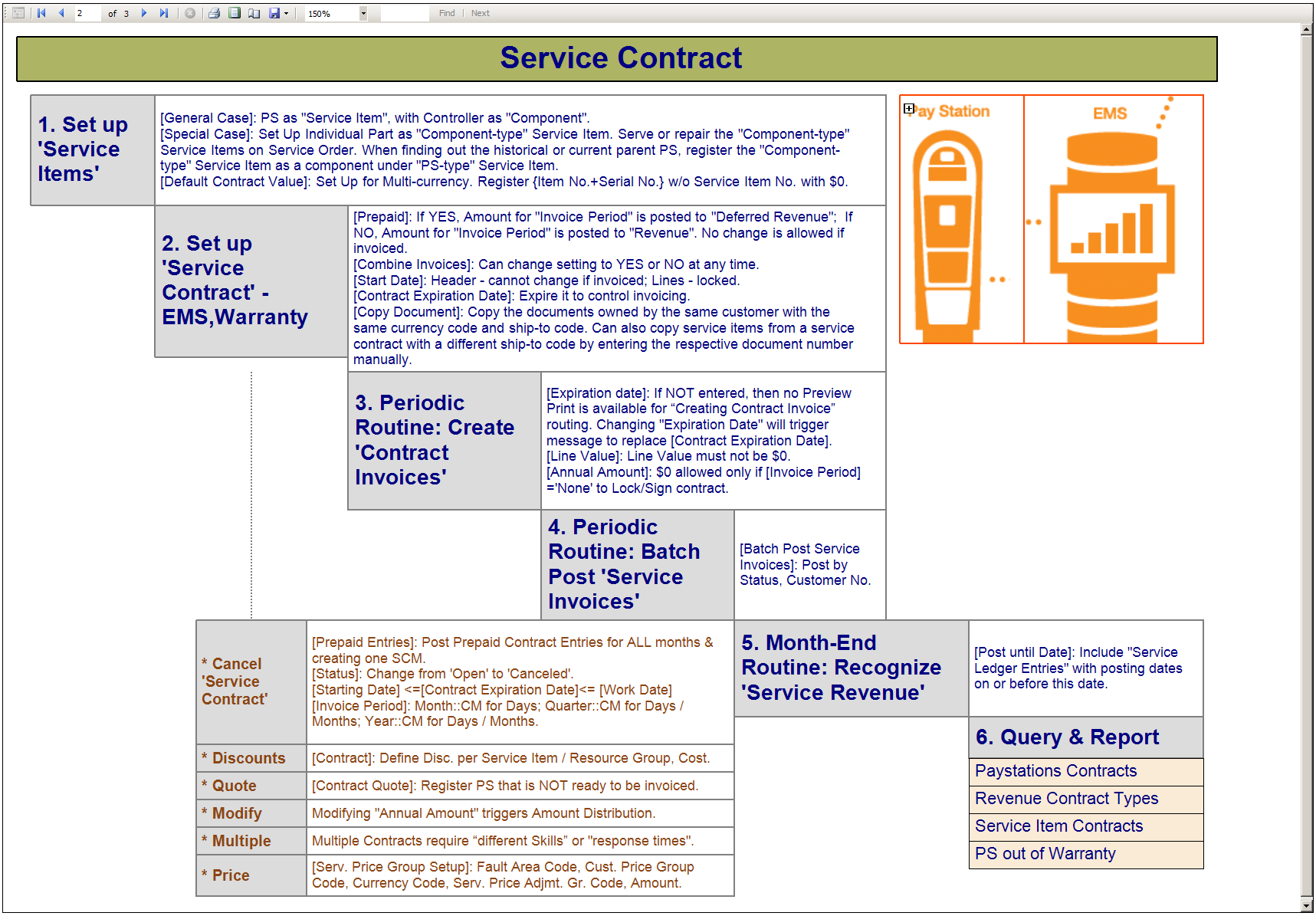

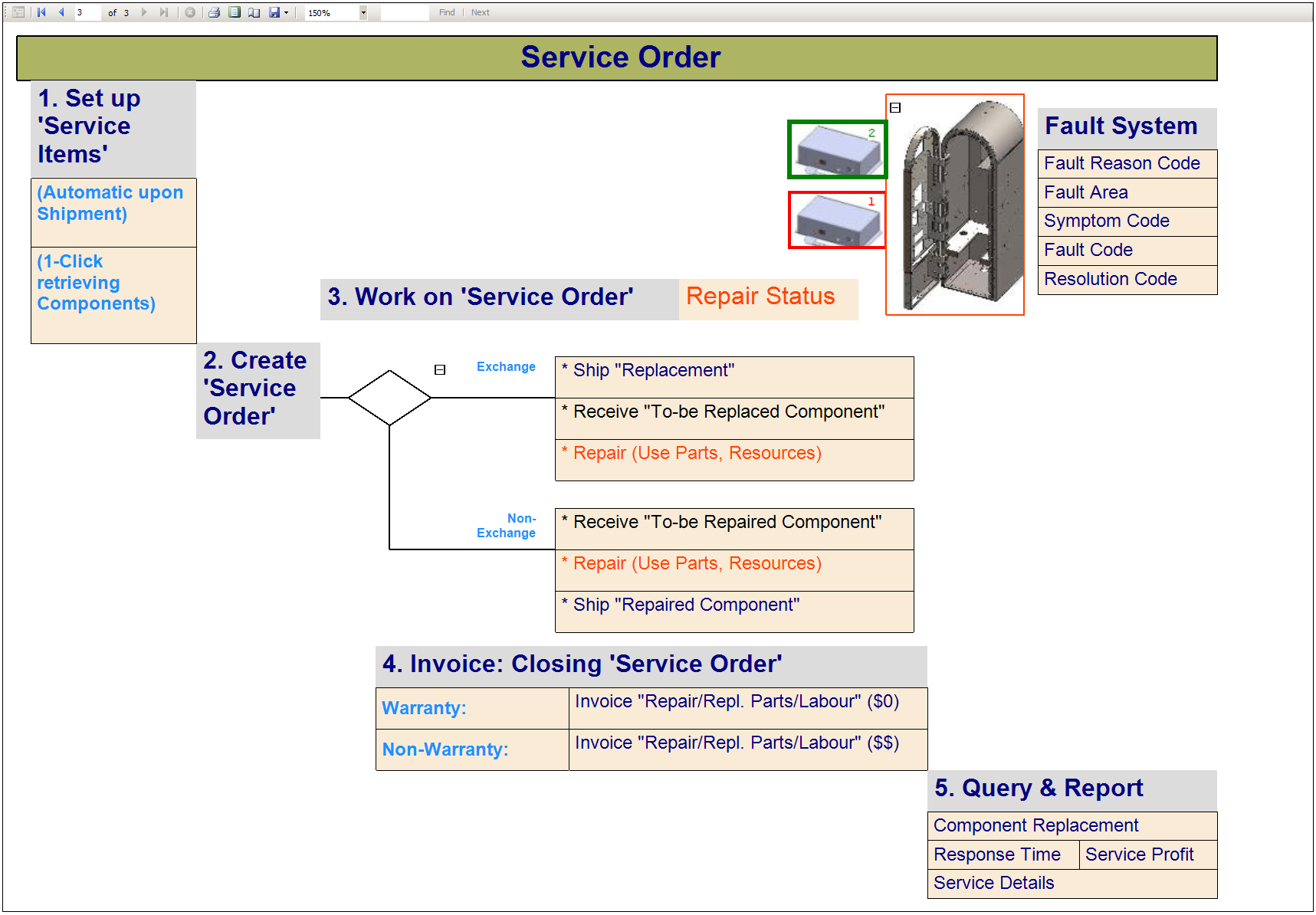

Upgrades often introduce new features that could help licensees do what they could not do or do things in better ways. However, most of the manufacturer’s business requirements could be handled by the existing version already, if it were configured, designed, and used properly.

Performance improvements

Upgrades often bring in performance improvements that could help boost applications’ stability and responsiveness. The manufacturer’s production facility did have slow connection to Navision and experienced crashes sometimes since the Navision hosting server moved to a new building a couple of blocks away. However, the problem is identified partially due to poor bandwidth and aging hardware.

Bug fixes and issue resolutions

The latest version often fixes bugs encountered in prior versions. Because of application’s broad customer base and the multiple environments in which they operate, software vendors are made aware of bugs quickly. There were many “hotfixes” applicable to the manufacturer’s version. More importantly, many of the “Material Resource Planning” features were re-written in the new version to make the module work “more correctly”. The most common, most recent issues faced by the majority of customers in older versions often have been resolved in more recent versions.

Backwards compatibility issues

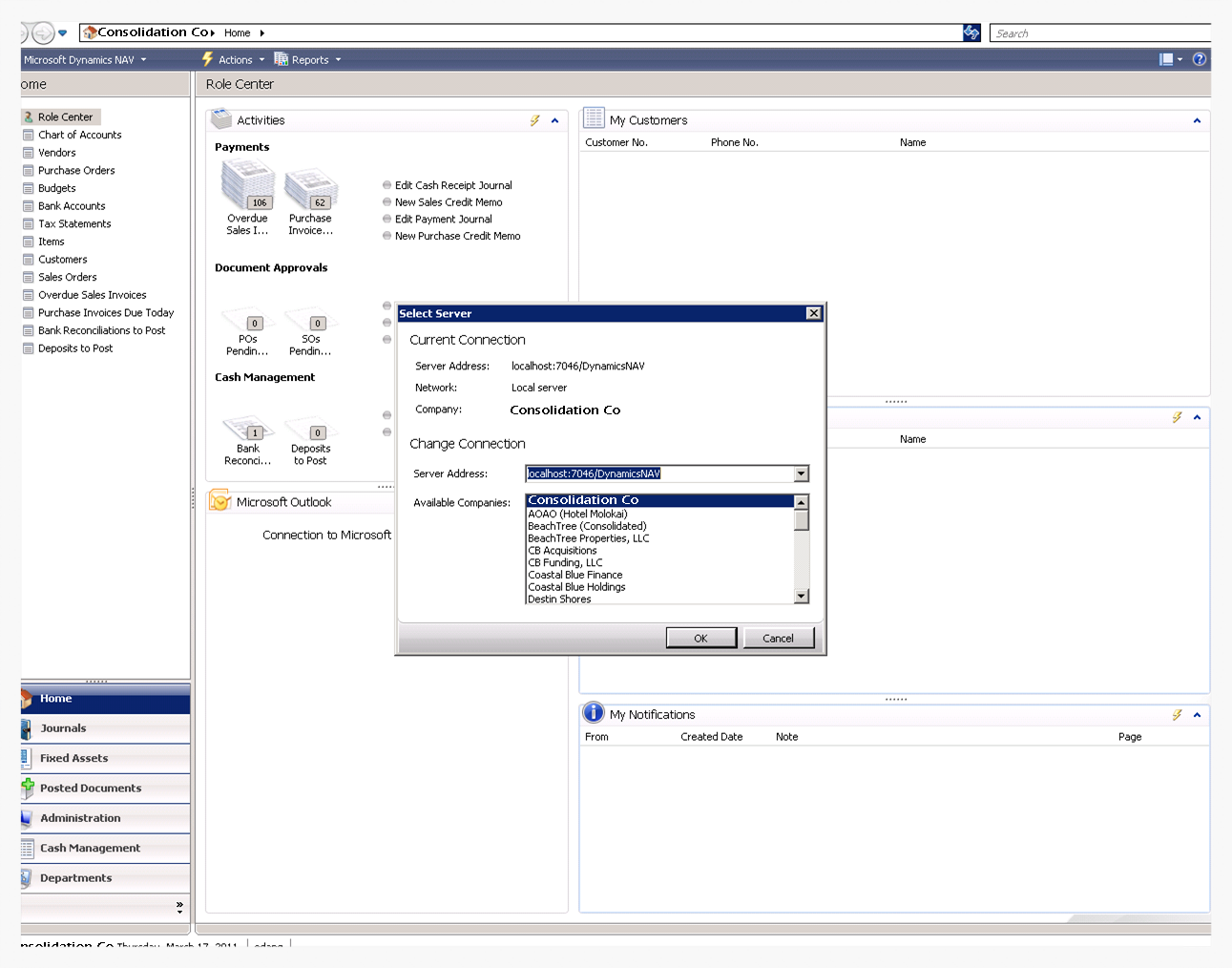

The company planned to upgrade all its desktops to Windows 7. NAV 4.0 (SP1/SP2/SP3) is not supported on Windows 7. Only Navision 4.0 SP3 with certain build could run on Windows 7 without running the Virtual Machine.

Maintenance automation

The company was on Navision Database, not on SQL Server. SQL Server offers the opportunity to automate backup procedures and NAV Database Mirroring with Hot/Warm Standby Servers with Maintenance Plans for High Availability and Disaster Recovery.

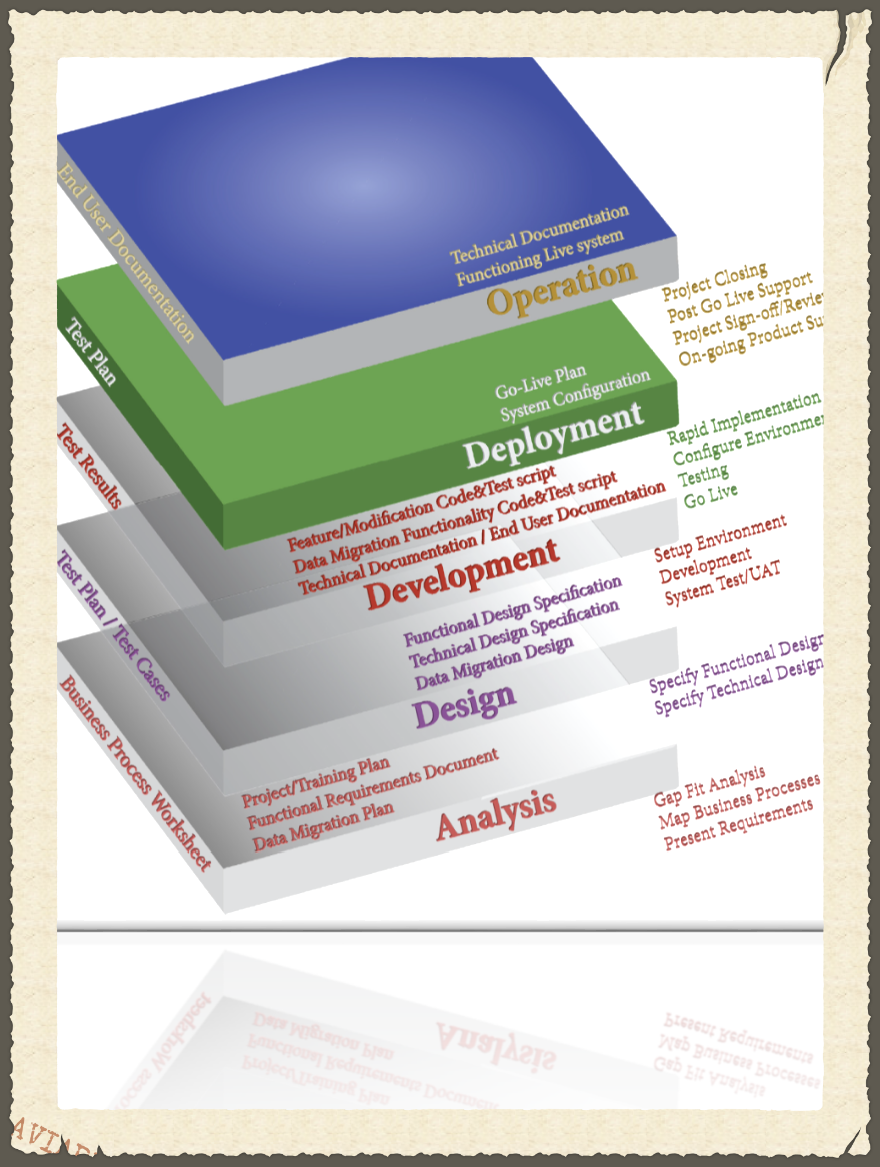

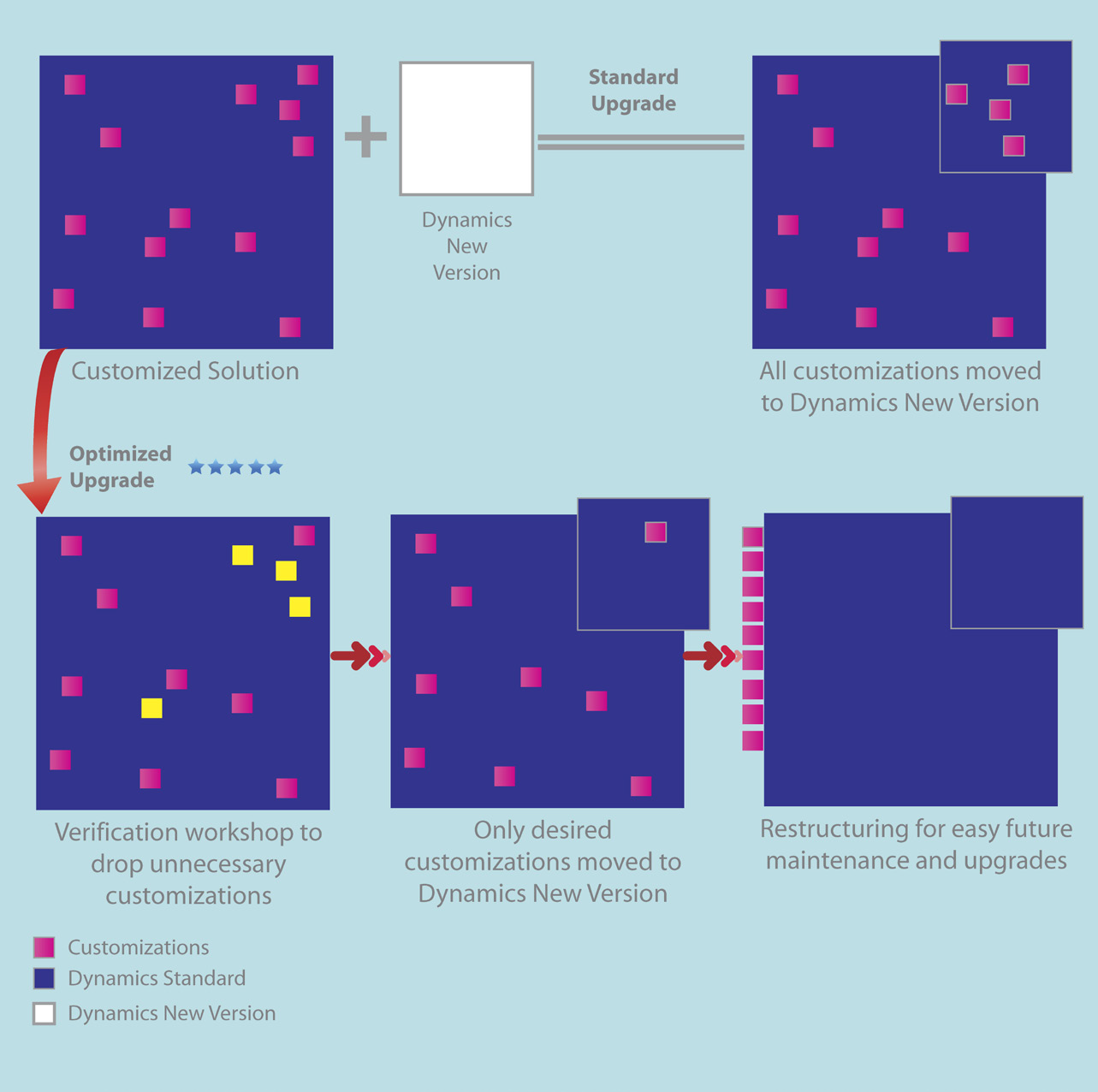

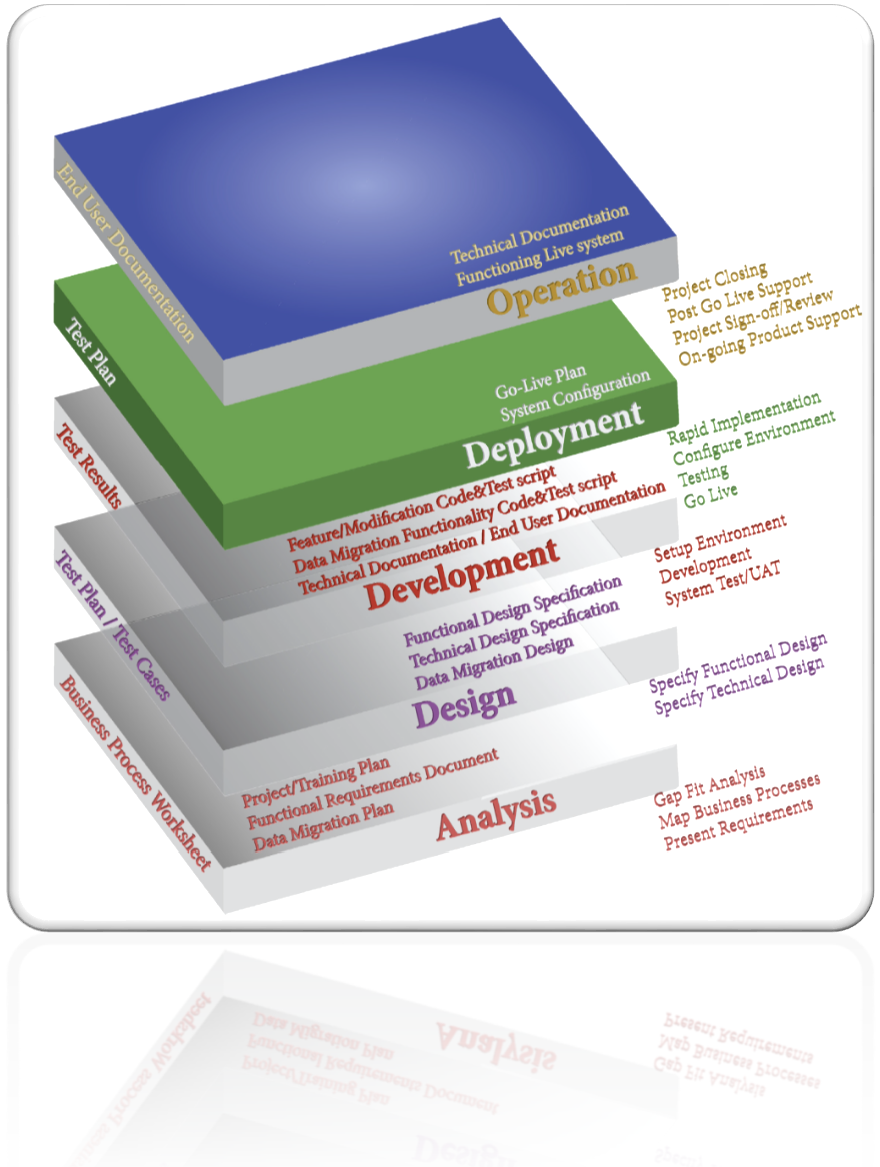

Upgrading With Confidence

The manufacturer saw the need to overcome compatibility issues due to the plan to move up to Windows 7 operating system. The manufacturer decided to upgrade to take advantages of new version of NAV after evaluating the cons and pros between “upgrade” and “deploying Citrix to facilitate old versions”. EBITA Systems was appointed as project manager to champion the upgrade.

Superior Expertise in System Conversion

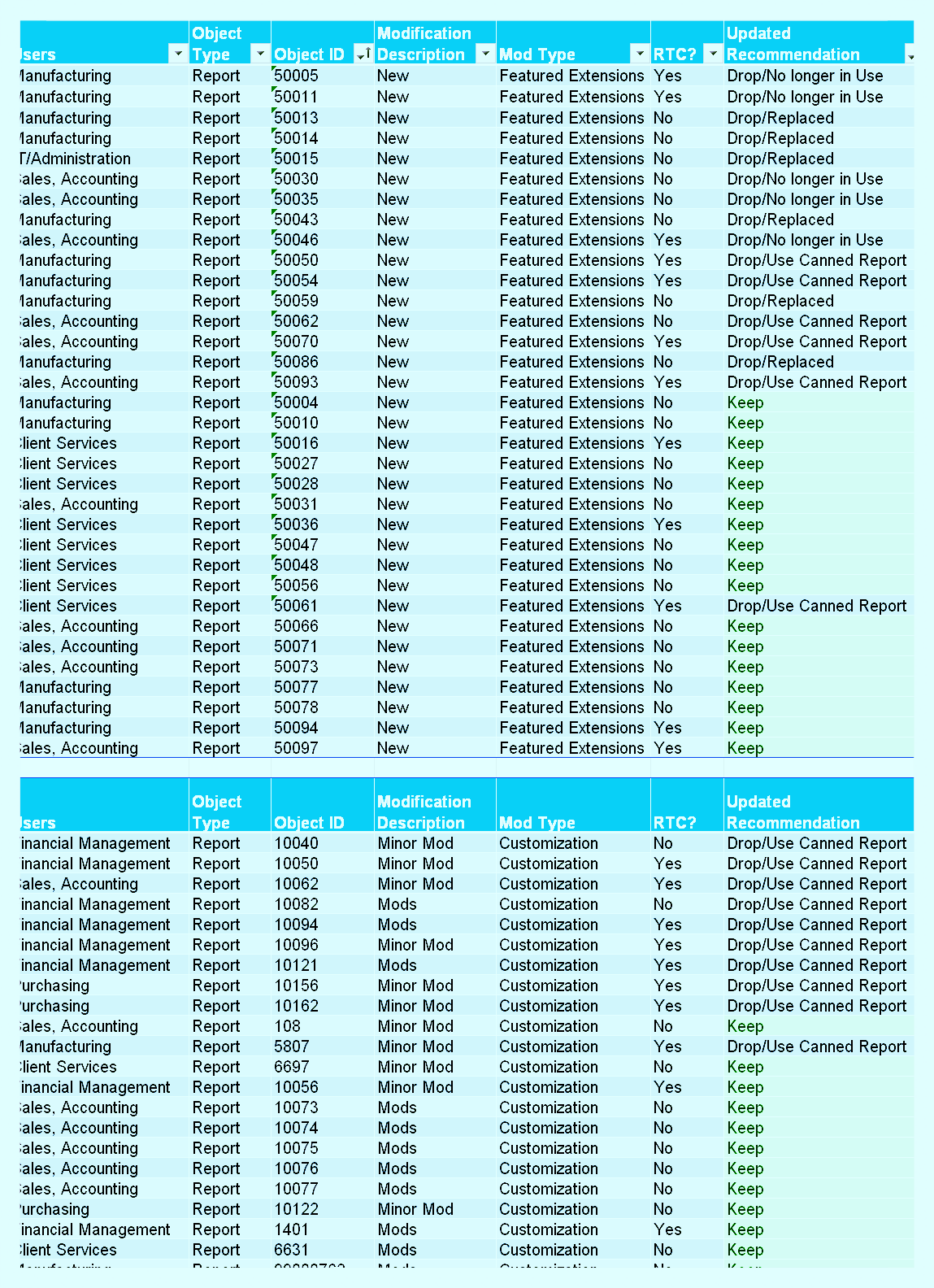

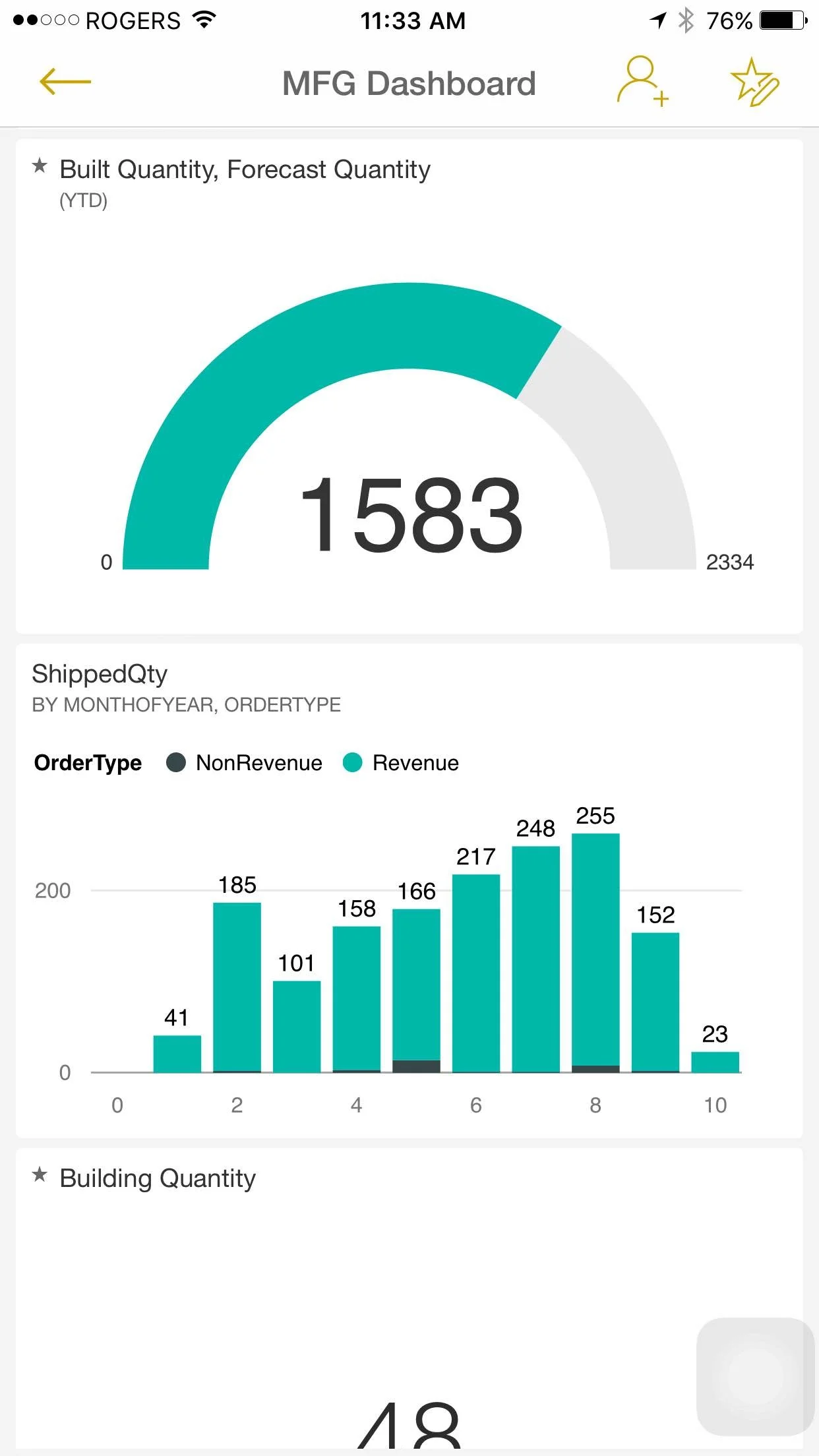

With limited resource from the manufacturer’s existing partner, EBITA Systems successfully led the upgrade project which delivered highly visible gain on performance and fresh user experience.

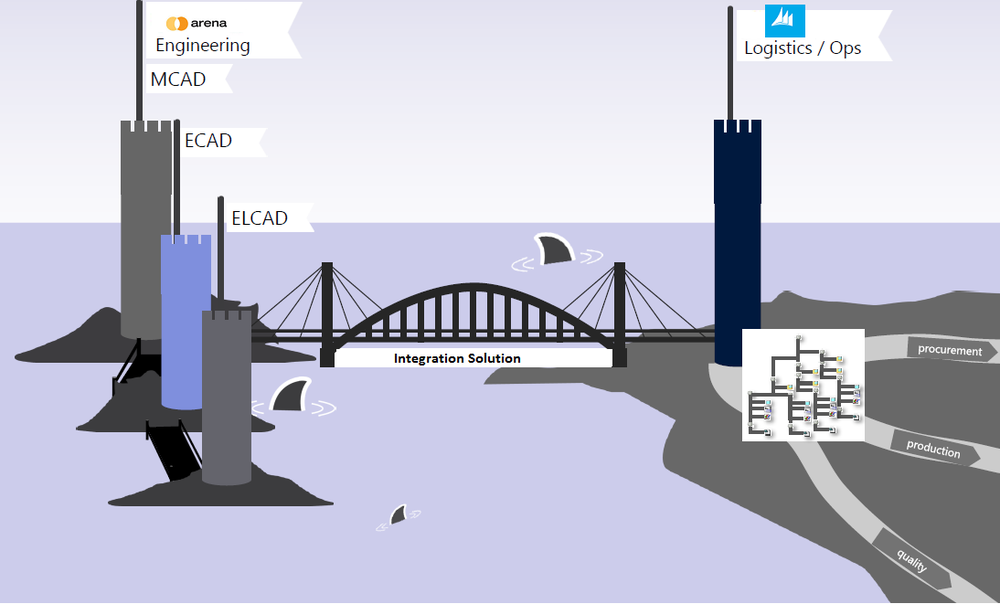

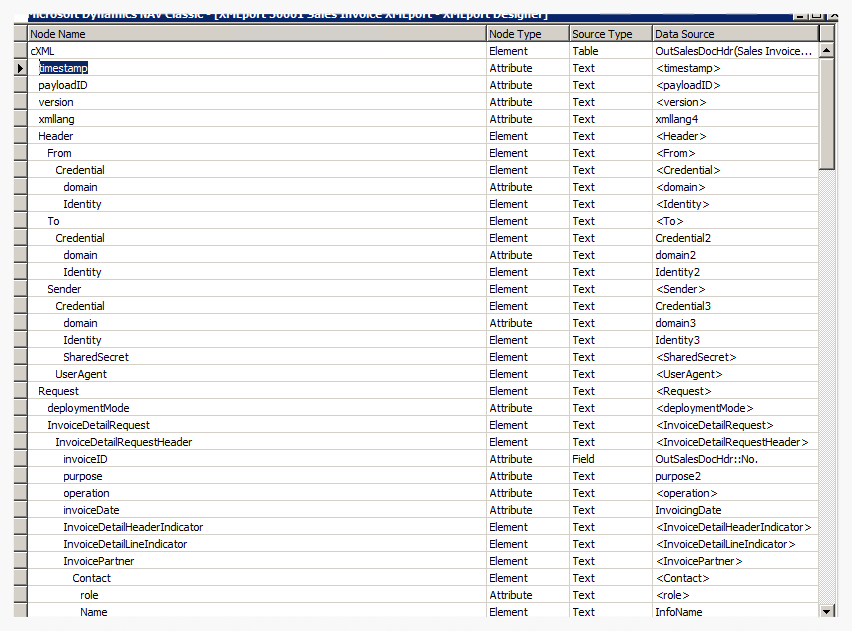

The upgrade project not only moved the manufacturer’s database to SQL Server, it also converted the system to offer dual clients - Classic Client and Role Tailored Client. The upgrade retained value-added customization. Outdated integration with Bar-code application was redesigned using new technology. The new system has been stable since the upgrade and gained enterprise-wide approval for performance and value.